We are delighted to announce that Nathan Ferrin, Chief Technology Officer at Cornerstone Automation, has been featured in the December 2023 Global System Integrator Report (GSIR). This summary highlights key aspects of the full article, detailing the successful control upgrade undertaken by the Cornerstone Automation team to enhance efficiency and productivity for Eastern Tea Corporation.

Operational Challenges at Eastern Tea

Eastern Tea Corporation, based in Monroe Township, NJ, faced operational issues with its 1991 Doboy flow wrapper and synchronous infeed conveyor. The equipment had malfunctioned, failing to synchronize product entry into the wrapper. Despite replacing many of the mechanical components over the years, the smart synchronizing conveyor’s effectiveness had diminished due to software obsolescence. Eastern Tea had resorted to manually pushing tea bags into the conveyor flights.

Significant Improvements with Control Upgrade

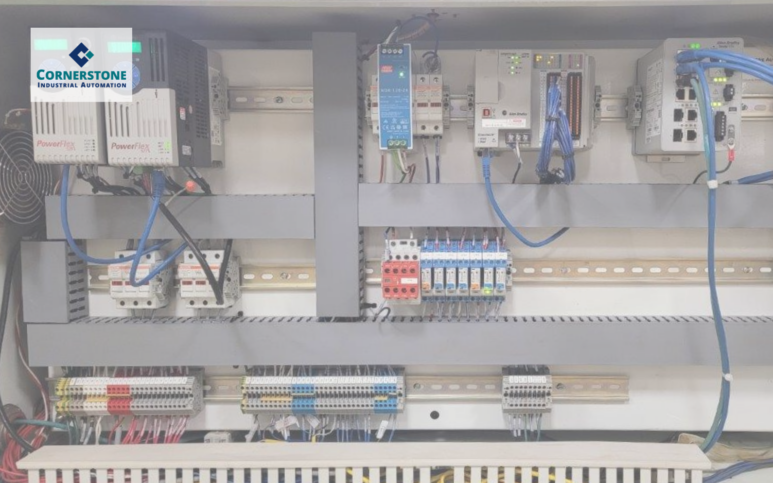

Upon contacting Cornerstone Automation in Souderton, PA, the company recommended a complete control upgrade due to the time-consuming process involved in repairing and reprogramming obsolete servo amplifiers. Despite challenges in parts sourcing, Cornerstone had been resourceful in procuring the necessary components at reasonable prices by combining a used vector drive and a new variable frequency drive (VFD) to create a temporary drive solution. The Allen-Bradley PowerFlex 527 servo drive and a standard three-phase induction motor were chosen for the upgrade.

The upgraded control system significantly improved Eastern Tea’s packaging process, enhancing conveyor synchronization and dynamic speed adjustments. These modifications resulted in increased operational efficiency, precise tea bag alignment, automated processes, and streamlined productivity. The full case study highlights the challenges faced in parts procurement, creative solutions employed, and the positive impact of the control system upgrade on Eastern Tea’s operations.

Streamlined Programming Approach for Control Upgrade

The programming approach simplified the process, utilizing only two motion commands in the programmable logic controller (PLC) and self-documenting code. The installation process was well-designed and executed, incorporating real-world measurements and flexible adjustments. The interlock mechanism was reverse-engineered, allowing for off-site panel fabrication and simulation to verify functionality before on-site implementation.

Machine Complexity and Efficient Solutions

The detailed full-length article provides insights into the machine’s complexity, focusing on modifications to the infeed section, consolidation of components, and the utilization of drawings to simulate signals exchanged between machine sections. The straightforward panel swap reduced downtime, and the upgraded system now relies on an advanced diagnostic interface for improved maintenance.

The upgraded machine, consisting of the infeed and flow wrapper sections, features two motors and three conveyors. The system ensures smooth operation by using motion access technology for minor adjustments based on specific conditions. The diagnostic capabilities offer enhanced monitoring, allowing for early identification of potential issues and reducing downtime.

Cost-Effective and Efficient Results from Control Upgrade

This comprehensive control upgrade proved cost-effective for Eastern Tea. The new system not only addressed the malfunctioning equipment but also provided advanced diagnostic capabilities, improving overall efficiency and reducing labor requirements. To read more in-depth details about the success of the control upgrade in terms of cost savings, consistent product quality, and enhanced machine performance, be sure to check out the full Eastern Tea Corp. case study in the Global System Integrator Report.